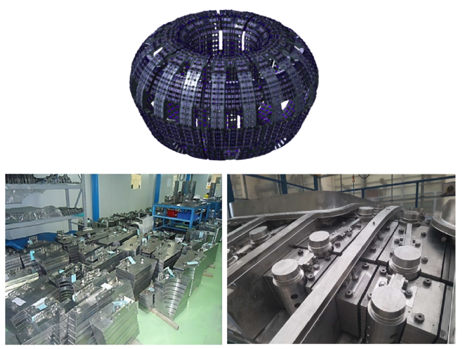

ITER-India, as a 10% stakeholder in ITER - one of the largest experiments in the history of mankind, added another feather to its cap in terms of achieving a major milestone related to the completion of manufacturing of the one of the nine procurement packages in active collaboration with M/s Avasarala Technologies, Bengaluru. The package termed as in-wall shields is a complex assembly of ~9000 borated steel blocks. The supplied shields are sandwiched between the double walls of the vacuum vessel of the ITER machine and perform the important function of shielding the components from neutrons and contribute to plasma performance by limiting perturbations due to toroidal field ripple. This is the third milestone achievement by India in a short span of less than year and speaks volumes of the dedication and devotion of all involved inspite of the existing pandemic conditions. The previous two milestones related to the handing over of the base section of the cryostat to ITER and its subsequent installation in the tokamak pit at ITER and the flag off of the final top lid segments of the cryostat from the premises of the M/s L&T Hazira. All components delivered to ITER meet the desired standards of safety and quality as per requirements defined by the French Nuclear Regulators. Indigenous development demonstrated the ever growing self-reliance related to the development of fusion technologies within the country for which both the industry and the scientists and engineers of ITER India, Institute for Plasma Research deserve an applause.

In this context, a video televised ceremony was organised. Speakers on the occasion included eminent scientist Dr. Anil Kakodkar, as the chief guest, Dr Bernard Bigot, Director general ITER organization, Dr. R.B. Grover. Shri K.N. Vyas, Chairman, Atomic Energy Commission conveyed his congratulatory message through Dr. Shashank Chaturvedi, Director IPR.

ITER is currently under construction in south of France at a nuclear site Cadarache is aimed at exploring and demonstrating a clean green economically viable alternate source of energy through nuclear fusion. The assembly activities are in full swing and the first plasma is expected in Dec 2025.

3D CAD model of the In-Wall Shield assembly; the manufactured plate assemblies from borated steel at Avasarala, Bengaluru and assembled in vessel sectors for ITER manufactured in Korea

Final consignment of In wall shields leaving the ATL premises